- Tungsten: history and industry development

- The history of tungsten dates back to the 17th century. Miners in the Erz Mountains of Saxony found that the presence of certain ores disturbed the reduction of cassiterite (a tin mineral) and induced slagging. The miners gave this ore German nicknames like "wolffram", "wolform", "wolfrumb" and "wolffshar".

- In 1758, Axel Fredrik Cronstedt, a Swedish chemist and mineralogist, discovered a heavy mineral. He called this special mineral "tungsten", which is Swedish for heavy stone. He believed that this mineral contained a new and undiscovered element.

In 1781, the outstanding Swedish chemist Carl Wilhelm Scheele discovered that a new acid, tungstic acid, could be made from scheelite. Scheele and fellow Swedish chemist and mineralogist, Torbern Bergman, proposed the possibility of getting a new metal by reducing this acid. In 1783, José and Fausto Elhuyar found that tungsten acid could also be made from wolframite. Later that year, in Spain, the de Elhuyar brothers clarified the constitution of the mineral wolframite and were the first to obtain the new metal through the reduction of this acid with charcoal. They named it wolfram, in consideration of the mineral from which it was extracted. Thereafter, this new chemical element and its compounds were studied by many scientists.

In 1781, the outstanding Swedish chemist Carl Wilhelm Scheele discovered that a new acid, tungstic acid, could be made from scheelite. Scheele and fellow Swedish chemist and mineralogist, Torbern Bergman, proposed the possibility of getting a new metal by reducing this acid. In 1783, José and Fausto Elhuyar found that tungsten acid could also be made from wolframite. Later that year, in Spain, the de Elhuyar brothers clarified the constitution of the mineral wolframite and were the first to obtain the new metal through the reduction of this acid with charcoal. They named it wolfram, in consideration of the mineral from which it was extracted. Thereafter, this new chemical element and its compounds were studied by many scientists.

- In 1855, people made the first attempt to produce tungsten steel, but industrial applications were impossible at that time due to the high price of tungsten metal. In 1847, a chemist named Robert Oxland came up with the first procedures for the preparation of sodium tungstate, the formation of tungstic acid, and the reduction to the metallic form by oil, tar or charcoal. He was granted patents for his work, which was regarded as an important step in modern tungsten chemistry, and opened the way to industrialisation.

- The first industrial application of tungsten was the alloying and hardening of steels in the late 19th century. Tungsten-containing steels were patented in 1858, which contributed to the first self-hardening steels in 1868. In 1900, high speed steels with tungsten additions up to 20% were first exhibited at the World Exhibition in Paris, and revolutionised engineering practice in the early 20th century. Thereafter, tungsten was applied in many fields.

In 1903, W. D. Coolidge made the second important breakthrough in tungsten applications. Coolidge succeeded in making very thin ductile tungsten wire. This was regarded as the beginning of tungsten powder metallurgy, leading to the rapid development of the lighting industry.

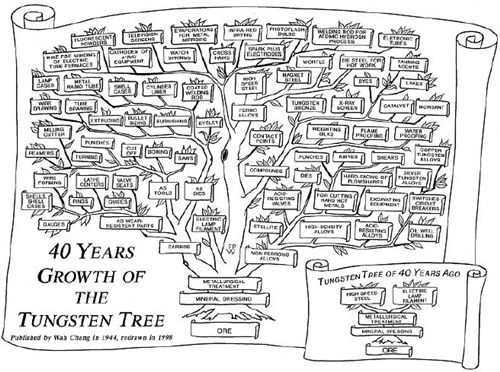

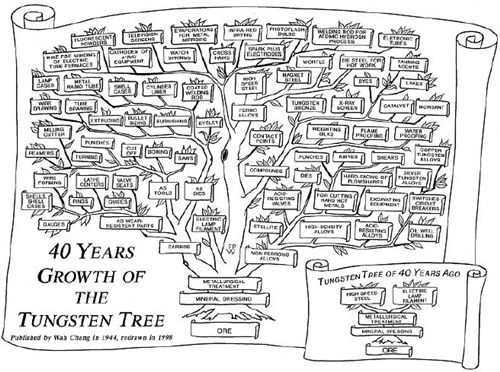

In 1903, W. D. Coolidge made the second important breakthrough in tungsten applications. Coolidge succeeded in making very thin ductile tungsten wire. This was regarded as the beginning of tungsten powder metallurgy, leading to the rapid development of the lighting industry.- The next important breakthrough was made in 1923 by K. Schröter. He is credited with the invention of hard-metal (combining cobalt and WC by liquid phase sintering). The corresponding application for a patent was granted to Osram Studiengesellschaft in Berlin and licensed to Krupp in Essen in 1926. In 1944, K C Li, President of Wah Chang Corporation in the US, published a picture in the Engineering & Mining Journal entitled: "40 Years Growth of the Tungsten Tree (1904 – 1944)" illustrating the fast development of the various tungsten applications in the field of metallurgy and chemistry.

- In recent years, the major tungsten consuming countries or areas have included China, the US, Japan and western Europe, while the major tungsten producing countries are China, Canada, Australia, Bolivia, Portugal and Thailand. As is well known, China is the world's largest tungsten producer. The country holds about 60% of the global tungsten reserves and typically contributes roughly 80% of global output. According to the United States Geological Survey (USGS), global tungsten production was around 71,000 metric tonnes in 2013, while the tungsten supply in China reached 60,000 metric tonnes. As to the consumption of tungsten, about half of the tungsten is used for the production of hard materials with the bulk of the remainder being used in alloys and steels, while less than 10% is consumed in other chemical compounds.

- Despite the rapid development of the tungsten industry in China, there still exist some problems, such as the low recycling levels, inefficient use of resources, and lack of high-end products. In order to solve these problems and promote sustainable development of the tungsten industry, the Chinese government has issued several measures on the exploration of tungsten ore and exporting of tungsten products.

-

About us

Contact us

Make a suggestion

- Metalpedia is a non-profit website, aiming to broaden metal knowledge and provide extensive reference database to users. It provides users reliable information and knowledge to the greatest extent. If there is any copyright violation, please notify us through our contact details to delete such infringement content promptly.

In 1781, the outstanding Swedish chemist Carl Wilhelm Scheele discovered that a new acid, tungstic acid, could be made from scheelite. Scheele and fellow Swedish chemist and mineralogist, Torbern Bergman, proposed the possibility of getting a new metal by reducing this acid. In 1783, José and Fausto Elhuyar found that tungsten acid could also be made from wolframite. Later that year, in Spain, the de Elhuyar brothers clarified the constitution of the mineral wolframite and were the first to obtain the new metal through the reduction of this acid with charcoal. They named it wolfram, in consideration of the mineral from which it was extracted. Thereafter, this new chemical element and its compounds were studied by many scientists.

In 1781, the outstanding Swedish chemist Carl Wilhelm Scheele discovered that a new acid, tungstic acid, could be made from scheelite. Scheele and fellow Swedish chemist and mineralogist, Torbern Bergman, proposed the possibility of getting a new metal by reducing this acid. In 1783, José and Fausto Elhuyar found that tungsten acid could also be made from wolframite. Later that year, in Spain, the de Elhuyar brothers clarified the constitution of the mineral wolframite and were the first to obtain the new metal through the reduction of this acid with charcoal. They named it wolfram, in consideration of the mineral from which it was extracted. Thereafter, this new chemical element and its compounds were studied by many scientists. In 1903, W. D. Coolidge made the second important breakthrough in tungsten applications. Coolidge succeeded in making very thin ductile tungsten wire. This was regarded as the beginning of tungsten powder metallurgy, leading to the rapid development of the lighting industry.

In 1903, W. D. Coolidge made the second important breakthrough in tungsten applications. Coolidge succeeded in making very thin ductile tungsten wire. This was regarded as the beginning of tungsten powder metallurgy, leading to the rapid development of the lighting industry.