As "The vitamins of modern industry", rare earth elements are of great importance in modern technology. Gradually their applications have become more widespread, which means their consumption is increasing and the reserves are declining. Therefore, a critical factor in the availability of rare earth elements is recycling. Especially for some rare earth metals resource-poor countries, whose supply chain is fairly limited, REE recycling could not only reduce costs, but also enable them to meet their needs--addressing the short supply of REE. Meanwhile, REE recycling could provide an economical and environmentally-friendly way to develop the REE industry globally.

As "The vitamins of modern industry", rare earth elements are of great importance in modern technology. Gradually their applications have become more widespread, which means their consumption is increasing and the reserves are declining. Therefore, a critical factor in the availability of rare earth elements is recycling. Especially for some rare earth metals resource-poor countries, whose supply chain is fairly limited, REE recycling could not only reduce costs, but also enable them to meet their needs--addressing the short supply of REE. Meanwhile, REE recycling could provide an economical and environmentally-friendly way to develop the REE industry globally. - At present, rare earth metals recycling is still in its early stages, the recycled raw materials are limited, including electronic waste and other wastes that have significant rare earth components, such as fluorescent lighting and computer hard drives. Meanwhile, there is no standard method of recycling rare earths and the technology for REE recycling is still not mature, meaning it is difficult and tedious to extract rare earth metals from these waste products.

- According to the EPA, in 2009, 25% of consumer electronics were collected for recycling (38% of computers, 18% of televisions, and 8% of mobile phones). Similarly, only 3-5% of compact fluorescent light bulbs (CFLs) are recycled. These may be the most readily available sources of recycled materials, so increasing the rate at which consumers recycle these key end products will be essential. In addition, once the technology improves, more and more high-tech raw materials such as waste from neodymium magnets, LCD screens that include rare earth phosphors-like europium, terbium and yttrium-as well as fluorescent light bulbs, could also be collected and used to extract REE.

- For instance, scientists are reporting the development of a new method for recycling rare earth elements from wastewater. New advances in recycling technology have made extraction of rare earths from these materials more feasible, and recycling plants are currently operating in Japan, where there is an estimated 300,000 tonnes of rare earths stored in unused electronics. Germany has been able to recycle 100-500 tonnes per year. What is more, in France, the Rhodia group is setting up two factories, in La Rochelle and Saint-Fons, that will produce 200 tonnes a year of rare earths from used fluorescent lamps, magnets and batteries.

(Source: www.molycorp.com/technology/rare-earth-recycling/)

As reported in "Rare earths recycling on the rise" Ana Komnenic | August 29, 2013

As reported in "Rare earths recycling on the rise" Ana Komnenic | August 29, 2013 - "A Massachusetts-based recycling facility has found a way to recover 99%-by weight-of a fluorescent lamp. Its next task is to extract rare earth elements (REE).

- "The company behind the technology, Veolia ES Technical Solutions, says it's able to separate most core components of the fluorescent lamp including glass, aluminium and mercury, according to Waste Management World. Now the recycler is working on also reclaiming rare earth elements from the phosphor powder used in the lamp's glass tube.

- "The centre currently processes more than 15 million pounds of lighting and electronic waste each year. The new facility will increase capacity for fluorescent lamps by 150%.

- "Veolia joins a number of companies looking to salvage REE from various products including cars, magnets and batteries. Earlier this year Honda began extracting more than 80% of rare earth materials from nickel-metal hydride batteries.

- "In general, with technology advancing step by step, the REE recycling system will become more and more complete in the future."

- Source: www.mining.com/rare-earths-recycling-on-the-rise-82348/

- Rare Earth Recycling Takes On New Luster

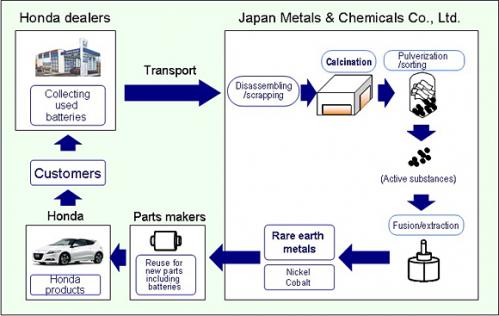

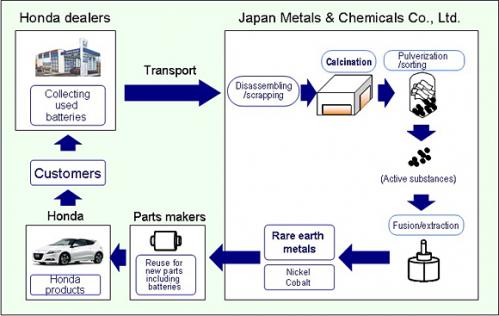

- One notable example is Honda's move in 2013 with Japan Metals & Chemicals (JMC) to start reusing rare earth substances in used nickel-metal hydride (NiMH) batteries in new ones after announcing its intention to do so in 2012. The automaker is using molten salt electrolysis to pull the materials out of an oxide extracted from the batteries: removing about 80 percent of what's in the original. Those substances are being supplied to a battery maker, which is using them for negative electrode materials in hybrid vehicle batteries.

- Belgian company Umicore actually made this commercially feasible even earlier than Honda. The company, which processes more than 350,000 tonnes of every year including industrial by-products, catalysts and end-of-life products, has a partnership with chemical company Rhodia that is also focused on NiMH.

- Rechargeable NiMH batteries are found in everything from cordless phones, toys and games to power tools to hybrid electric vehicles. There's about 1 gram (0.03 ounces of rare earth stuff in an AAA battery and up to 2 kilograms (4 pounds, 6 ounces) in a hybrid EV battery. Lithium-ion batteries don't have the same recovery potential.

- "In the short term, we think recycling will be one of the few rare earth plays with upward motion," writes cleantech analyst Dallas Kachan, in his 2014 annual predictions blog. "Why? Much of the industry has been focused on new mines to meet growing demand for rare earths. But recycling of rare earths is gaining momentum quietly, and stands to accelerate in 2014 given the increasing costs of mining and cost and schedule overruns at high profile sites like Molycorp's Mountain Pass California mine.

- Aside from Honda, two other big companies talking up rare earth recycling and recovery include Mitsubishi Electric (which is recovering them from air-conditioning compressors) and Veolia Environmental Services (which plans to begin recovering them from 15 million pounds of e-waste and lamps at a facility in West Bridgewater, Mass.)

- Source: http://www.forbes.com/sites/heatherclancy/2014/02/25/rare-earth-recycling-takes-on-new-luster/

-

About us

Contact us

Make a suggestion

- Metalpedia is a non-profit website, aiming to broaden metal knowledge and provide extensive reference database to users. It provides users reliable information and knowledge to the greatest extent. If there is any copyright violation, please notify us through our contact details to delete such infringement content promptly.

As "The vitamins of modern industry", rare earth elements are of great importance in modern technology. Gradually their applications have become more widespread, which means their consumption is increasing and the reserves are declining. Therefore, a critical factor in the availability of rare earth elements is recycling. Especially for some rare earth metals resource-poor countries, whose supply chain is fairly limited, REE recycling could not only reduce costs, but also enable them to meet their needs--addressing the short supply of REE. Meanwhile, REE recycling could provide an economical and environmentally-friendly way to develop the REE industry globally.

As "The vitamins of modern industry", rare earth elements are of great importance in modern technology. Gradually their applications have become more widespread, which means their consumption is increasing and the reserves are declining. Therefore, a critical factor in the availability of rare earth elements is recycling. Especially for some rare earth metals resource-poor countries, whose supply chain is fairly limited, REE recycling could not only reduce costs, but also enable them to meet their needs--addressing the short supply of REE. Meanwhile, REE recycling could provide an economical and environmentally-friendly way to develop the REE industry globally.  As reported in "Rare earths recycling on the rise" Ana Komnenic | August 29, 2013

As reported in "Rare earths recycling on the rise" Ana Komnenic | August 29, 2013